|

| |||||||||||||||||||||||||||||||||||||||

|

|

#3 | ||||||

|

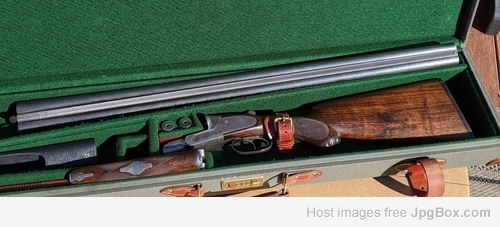

Well, after a long, cold and snowy winter followed by a hot-cold-hot-wet spring then the same for summer here in central Ohio, my 1893 Parker GH project is now completed. The barrels are back home, looking top-shelf fantastic, reunited with the recheckered fore-end, mullered border, all lines recut with fresh shellac, and the cleaned stock/receiver. This was a fun project and now it's back in the safe until autumn.

Here are a few photos to close out this thread. Pheasants starting in September and woodcock in November await. Quail to follow next April. To all who helped with advice and encouraging comments along the journey, my hearty thank you. |

||||||

|

|

|

||||||

| The Following 7 Users Say Thank You to Cameron Thraen For Your Post: |

|

|

#4 | ||||||

|

Craig, thanks for the reply. See next post.

|

||||||

|

|

|

||||||

|

|

#5 | ||||||

|

Craig, thanks for the reply. Will your provide some more detail or context as I am having difficulty visualizing your description of this tool? Thanks.

|

||||||

|

|

|

||||||

|

|

#6 | ||||||

|

Cameron, take a 1/2" wood dowel 4" long. Drill a 1/8"hole in the center of the dowel 1/2" deep. Now take a 4-40 or 5-40 screw at least 1-1/4" long and generate a 1/2" radius using a propane torch. Epoxy the screw in the dowel and allow it to cure. Its ready for use. The die sinker file I use is German and will set you back about $40. Mine was given to me. I would not recommend the cheap Chinese die sinker files for mullered borders.

|

||||||

|

|

|

||||||

|

|

#7 | ||||||

|

I have found that refinishing the wood prior to recuttingthe checkering gives a better job and the checkering comes out better then light finish on new checkering so as not to clog up.

|

||||||

|

|

|

||||||

| The Following User Says Thank You to Jim DiSpagno For Your Post: |

|

|

#8 | ||||||

|

Parker checkering is NOT flat bottomed. That video by potterfield was not accurate in stating/doing that on that gun.

A mullered border can be cut with a dembart concave border cutter. Or with a U-gouge. Or by using the altered machine screw that craig describes. Or even a rifler file can use used.

__________________

B. Dudley |

||||||

|

|

|

||||||

| The Following 4 Users Say Thank You to Brian Dudley For Your Post: |

|

|

#9 | ||||||

|

Thanks to all. Craig I now have what you are describing fixed in my head. Appreciate the clarification. Do you have a photo? That would be useful.

Brian, thanks. I will add a comment to Potterfield YT channel on this error. Save me the time and expense of making a flat bottom cutter and messing up my Parker. Really appreciate it as drill rod is cheap, 01 Swiss checkering file is decidedly not. So, what did the Parker Bros use to create the flat top checkering ? A 60 degree single line cutter? |

||||||

|

|

|

||||||

|

|

#10 | ||||||

|

Just thinking ahead. Any advice on using alkanet root as a stain on this Parker? I have read quite a lot on AR as a stain to get that red tone but I am not sure about using it on my 1893 Parker? I do not make my own of course but am aware that a product by S.B. McWilliams can be purchased on eBay. Looking for your advice. Thanks.

A note: On my project gun from last winter (Leftover G S#47216: Stock repair- yikes on the Double gun forum) I used Brownell's Pilkington spirit stain and then multiple hand rubbed coats of Velvit Oil. Turned out very satisfactory.

|

||||||

|

|

|

||||||

|

| Thread Tools | |

| Display Modes | |

|

|