Pat,

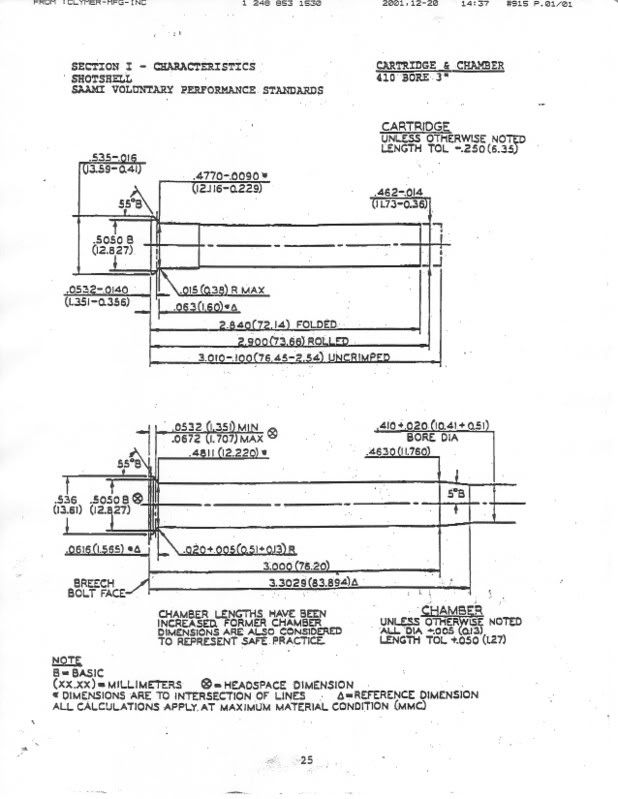

The drawing shows the cartridge on top and the chamber below. If it's not readable, I'll email it to you.

Minimum dia at the back of the chamber is .476" and .458 at the front end.

Yes, most manufacturers will continue to use a reamer after it begins to dull. My Beshi NID copy had really tight chambers, clearly from a over used and probably resharpened chamber reamer. I bought a Clymer reamer "drilled it out" and life was good again. I also lengthened my forcing cones with a thing Bill calls a drill but is really a custom made reamer I had a friend in the cutter industry make for me. It cuts a 3" long forcing cone in a .410. Then I polish the hell out of the forcing cone. If I ever get my barrels from CSM, I'll lengthen the cones (to reduce recoil of course

) as soon as I ensure they are fitted and functioning correctly.