Thanks everyone.

I just realized that one of my pics fortuitously illustrates the observation I made earlier about the original wood-to-metal contact being typically better around the edges of the stock than in the center, thereby concentrating recoil force around the outer surface.

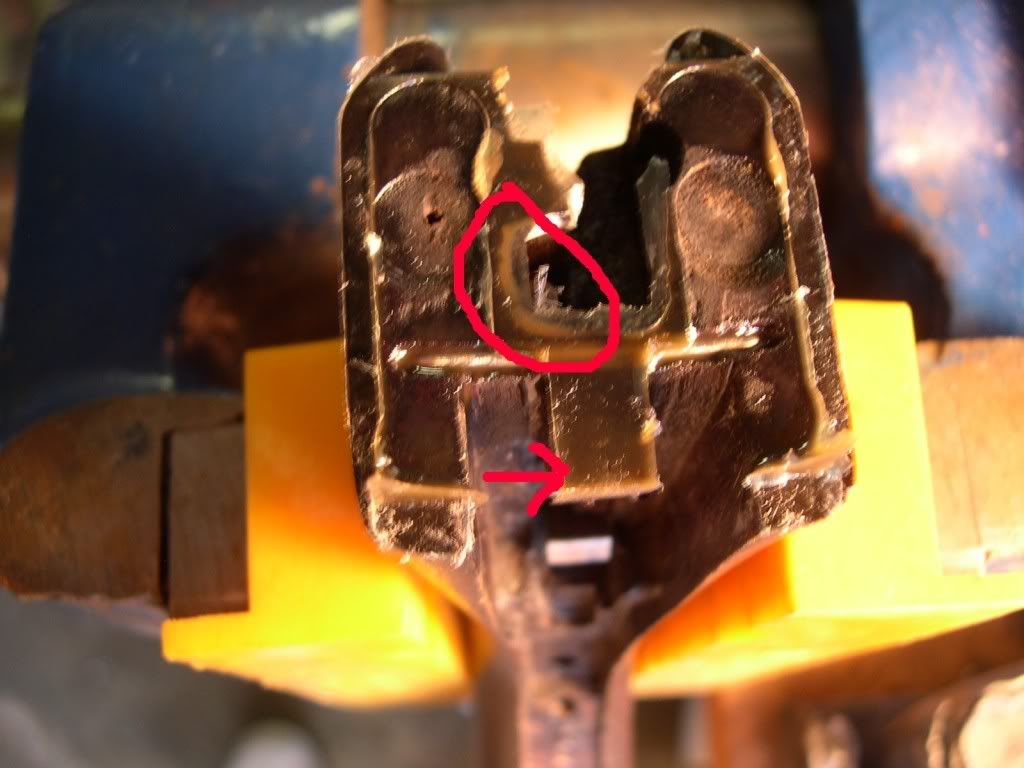

In the pic below (post-bedding), the stockface wood is very dark brown since it has been previously saturated with thin CA glue to seal/toughen it prior to the bedding. The epoxy is a lighter, caramel color. In the areas where the wood-to-metal contact is very good, the epoxy gets squeezed almost entirely out and the resulting layer left behind is so thin it is transparent and the dark brown wood underneath shows right through. In the areas where the fit is not as good, less epoxy gets squeezed out leaving a thicker layer behind to fill the gap. The thicker areas show up as the caramel color of the epoxy itself, since it is too thick to be transparent and the dark wood underneath is not visible through it. The red arrow indicates the thicker area of epoxy near the bottom of the square-shaped piece of inletting, and you can see the fit is better just above where the caramel color gives way to the dark brown wood underneath as you move upwards towards where the staple is placed. It is also apparent that there was a good fit all around the edges of the stock because those areas show no appreciable thickness of the Acraglass. In the circled area a smaller area of thicker epoxy is visible where the fit wasn't as good. Glass-bedding fixes these areas on poor contact, of course.[IMG]

[/IMG]