|

| ||||||||||||||||||||||||||||||||||||||

|

|

#3 | |||||||

|

Quote:

Joe |

|||||||

|

|

|

|||||||

|

|

#4 | ||||||

|

Chuck,

I've looked at your post over on doublegun and these pictures should answer one of your questions about the BT forend iron & latch. The main difference in the two forend irons is the beavertail has the extra support rod/screw that runs down the rib channel. Look closely at the top view of the two together and you can see an extension of the beavertail iron for the thread boss that the support screw interfaces with. I've seen several after market BT's that have been broken for the lack of the extra support. |

||||||

|

|

|

||||||

|

|

#5 | ||||||

|

I once owned two, two-barrel sets in 12 ga. One beaver tail one splinter, one DT one SST chokes ranged from full to Q1 and the barrels were all interchangeable two 26" & 2 28"... yep you guessed it, I sold them... ug.

|

||||||

|

|

|

||||||

|

|

#6 | ||||||

|

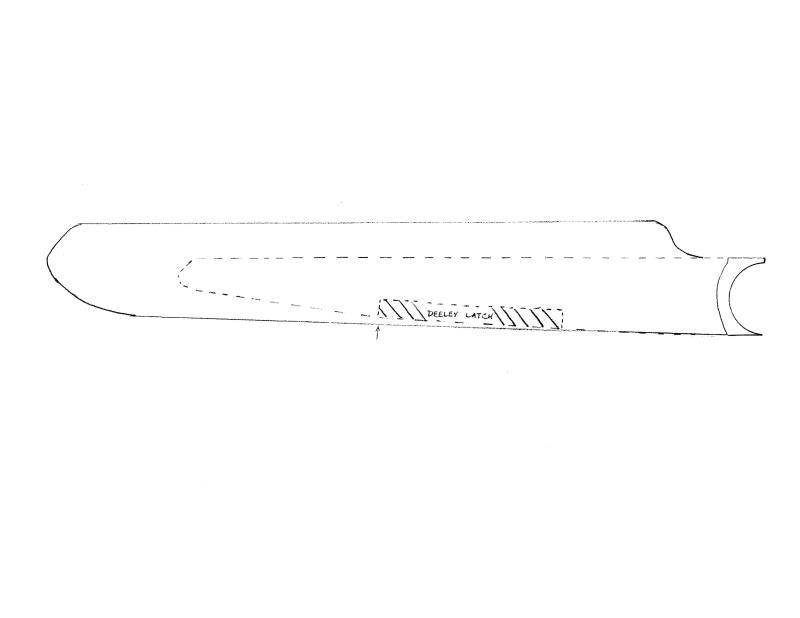

What I was curious about with the Parker BTFE's is whether the latch depth was the same. On many doubles, the latch for a splinter has a different paw and allows the splinter to be a thinner profile than the BTFE. Many conversions to BTFE from splinters require that that latch be inset below the surface because the latch paw length is not correct for a BTFE. (see sketch below)

|

||||||

|

|

|

||||||

|

|

#7 | ||||||

|

From my observations I am of the opinion that the assembled forend iron and latch from either type of forend are the same depth. Anyone with a gun that has both a splinter forend and beavertail or "trap" forend should be able to measure one against the other. I know John Dunkle's Grandfather's wonderful AAHE Double Trap has one of each style of forend... maybe John would be good enough (if he's currently at home) to take some quick measurements.

|

||||||

|

|

|

||||||

|

|

#8 | ||||||

|

Chuck, as I said (yes, Dean, I said it before

), it doesn't seem possible to measure the thickness of the forend metal accurately without removing the wood (which I prefer not to do). As Dean said, I'm pretty sure they are the same thickness because both the beavertail and splinter will go on the same barrels, and both are inlet flush with the bottom of the wood. When I get home on Thursday (out of town now), I'll see if I can measure them somehow, but I'm almost positive they are the same. I can send a picture from the side, but I don't think it will answer your question (the wood hides all the metal from a side view). ), it doesn't seem possible to measure the thickness of the forend metal accurately without removing the wood (which I prefer not to do). As Dean said, I'm pretty sure they are the same thickness because both the beavertail and splinter will go on the same barrels, and both are inlet flush with the bottom of the wood. When I get home on Thursday (out of town now), I'll see if I can measure them somehow, but I'm almost positive they are the same. I can send a picture from the side, but I don't think it will answer your question (the wood hides all the metal from a side view).Joe |

||||||

|

|

|

||||||

|

|

#9 | |||||||

|

Quote:

Chuck, what you are referring to is a non-Parker "BTFE from splinter" conversion which are almost invariably (unless done by an expert stocker well versed in Parker shotguns) much thicker than would be an original or correctly done replacement. The usual Parker Bros. and Remington Parker BTFEs were wide and flat and the barrels sat quite low into the wood. I have seen the kind you refer to and unfortunately they usually are abominations. |

|||||||

|

|

|

|||||||

|

|

#10 | ||||||

|

Actually Joe, I can think of a couple of ways to measure the depth or thickness of both types of forend on the same gun. The first way is probably the simplest. Begin with a flat, stable, unobstructed work surface. Lay the inverted gun on the work surface (top rib down) with the bead just off the edge of the surface. With one type of forend or the other firmly in place on the barrels measure the distance from the work surface to the highest point of the latch and record it. Now measure from the work surface to the lowest point of the latch in order to establish an angle if such angle exists. Record this number. Now, replace the forend with the other type of forend and repeat the process. I suggest the measurements should be the same.

|

||||||

|

|

|

||||||

|

|

|